Engineering Services

Butler National offers a spectrum of engineering (mechanical, electrical, and software) support. We take ideas from concept to finished product.

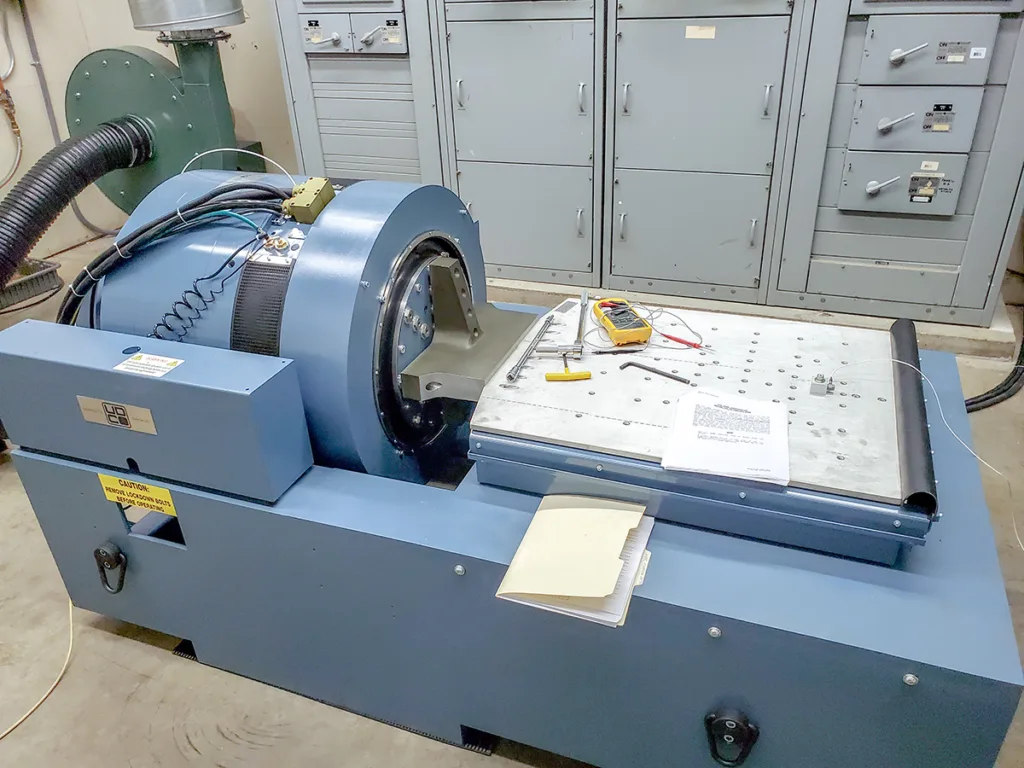

The Butler National Transient Suppression Device protected the fuel tanks of classic Boeing 737 and 747 aircraft from transient energy.

Why Butler National?

Whether improving a small sub-component or designing an entirely new concept, Butler National has the skills and process for product development.

Our engineering team includes various skill sets for product and system design, with decades of experience in mechanical, electrical, and software engineering.

All engineering and design activities are conducted at our parent company’s facility in New Century, KS.

About Our Services

BNC specializes in the design, manufacturing, delivery, and service of rugged, mission-critical electronics for the Aerospace and Defense industries. We work with purpose-built small-form-factor (SFF) electronic components that are qualified to MIL-STD specifications. We also manufacture environmentally-qualified cabling in-house. High-complexity, low-volume manufacturing is a specialty.

Full-Service Engineering

All phases of the production process are managed in Butler National facilities. From idea to circuit board design, procurement and assembly – Butler National maintains complete product integrity. This allows us to take a comprehensive approach to the design of enclosures, integrated switches, hardware, and software to create a reliable end product.

Technical Services

We offer technical services, including qualification testing, integration, flight testing and support. We provide preventative maintenance and support programs to our customers for the entire life-cycle of our products. Furthermore, we have extensive experience redesigning legacy products to keep them viable and capable of withstanding modern challenges.

Capabilities & Certifications

- AS-9100D / ISO 9001:2015

- Mechanical Engineering

- Electrical Engineering

- Software Engineering

- Manufacturing & Assembly Capabilities

Areas of Expertise

Butler National derived its skillsets from decades of design and manufacturing mission-critical avionics and defense electronics.

PCB Design & Assembly

Butler National populates product-specific Printed Circuit Boards on-site in its Tempe, Arizona manufacturing facility using state-of-the-art pick-and-place operations with reflow soldering.

Control Logic

Butler National develops proprietary control logic software / firmware for its products. Our new software development process is MIL-STD-882 compliant.

Cabling & Wiring Harnesses

BNC uses proprietary manufacturing techniques to design and fabricate quality cabling solutions for a variety of ruggedized systems.

Electronics Encapsulation / Enclosures

Butler National designs and manufactures ruggedized enclosures for electronics and electromechanical products. We frequently qualify our enclosure designs to MIL-STD-461 and MIL-STD-810.

COTS Components

Butler National uses commercial-off-the-shelf parts in its products to improve maintainability and reduce cost.

SWaP-C Optimization

Butler National products are fielded in helicopters and ground vehicles, where size and weight come at a premium. We optimize for Size, Weight, Power, and Cost (SWaP-C).

Systems Integration

Butler National applies its expertise for seamless integration of our products into larger systems.

Long-Term Service & Support

Butler National services include prototype design and manufacturing, service/overhaul, supplemental production, and product updates/upgrades. We also offer technical services and installation support.

Personalized Contact

Butler National offers personalized contact with project stakeholders every step of the way for delivery of a high-quality end product.

BNC: Supporting the missions that matter most.

From controlling the guns on the latest military vehicles to protecting the fuel tanks of commercial aircraft, Butler National Corporation products serve mission-critical roles in sectors where failure is not an option.